Box Smarter with Right-Sized

Automated Packaging

Box Smarter with Right-Sized Automated Packaging

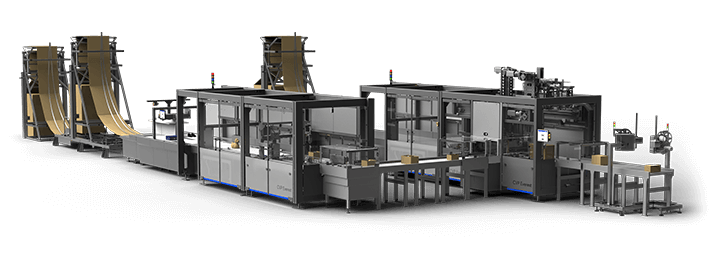

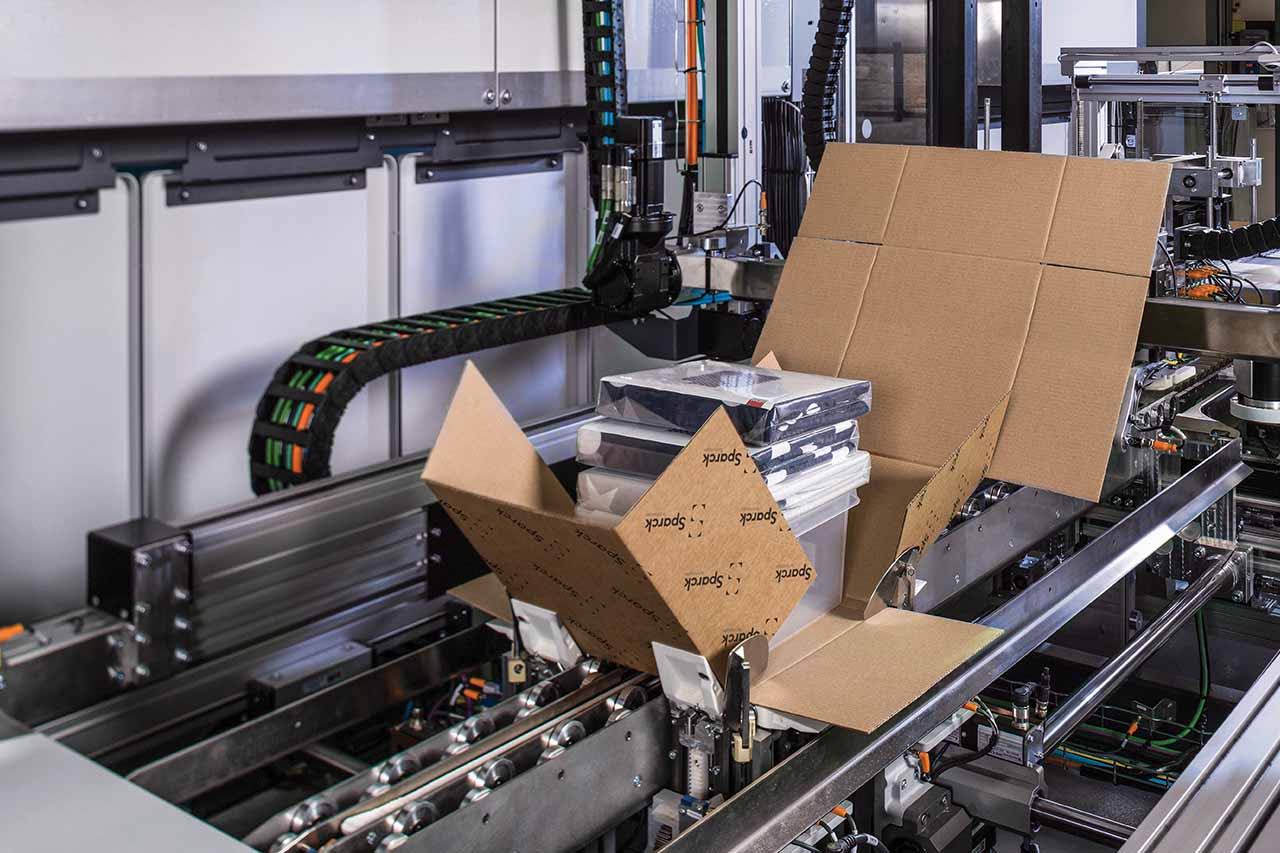

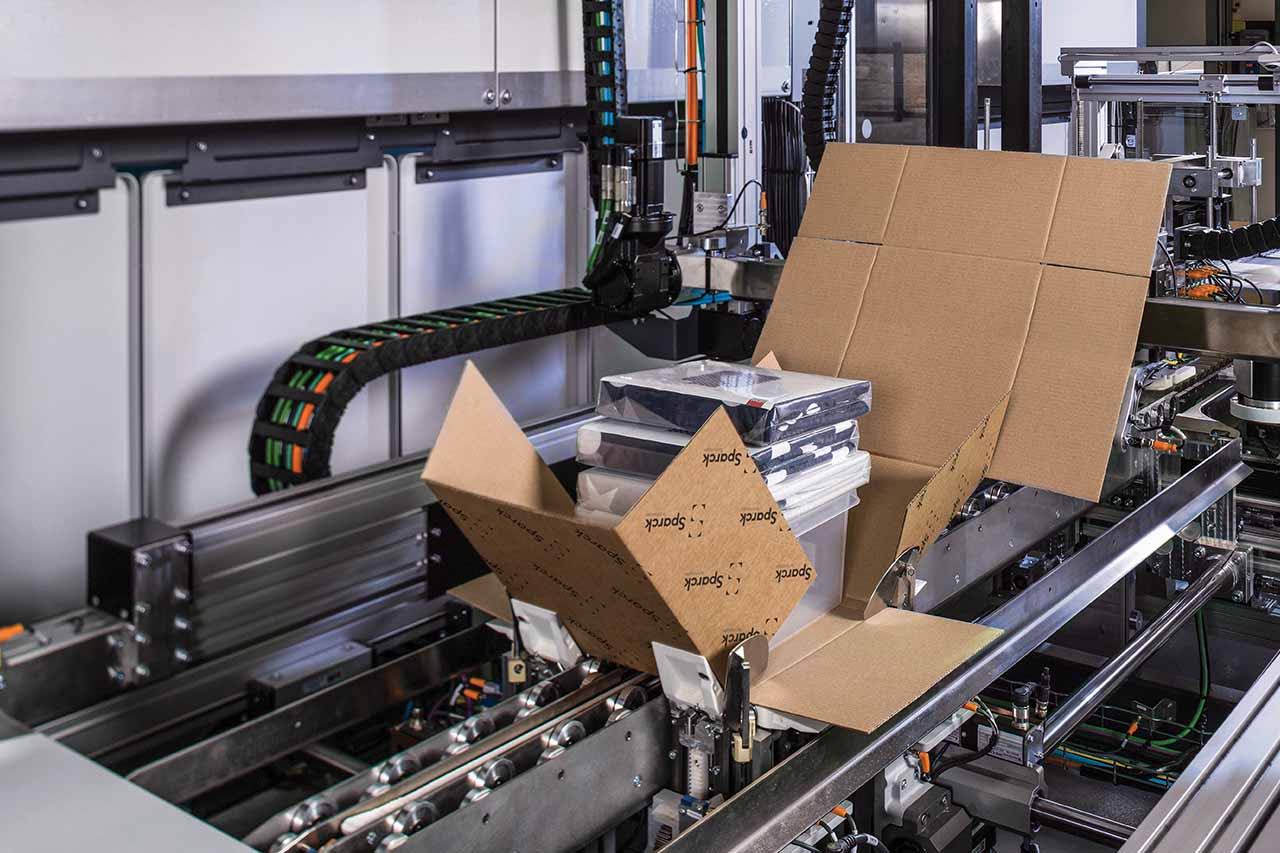

The CVP Automated Packaging Solutions are inline auto-packers. Made by Sparck Technologies, this fit-to-size packaging technology will size, construct and label each custom order, creating the perfect package and eliminating the need for void fill materials. Automated packaging allows you to keep pace with the increasing numbers of online orders even during peak times. Companies worldwide benefit from a seamless packing process, saving labour costs while reducing box volume and corrugate consumption.

How does automated packaging work?

Place order on induct station

Place order on induct station

Single- or multi- item orders can be processed by one operator for maximum packaging productivity.

Fit-to-size packaging

Fit-to-size packaging

Each unique order is 3D-scanned to determine the minimum box size required. Corrugate is custom cut to eliminate unnecessary volume and the need for void fill. Order is then auto-packed in a fit-to-size box.

Fit-to-size packaging

Fit-to-size packaging

Each unique order is 3D-scanned to determine the minimum box size required. Corrugate is custom cut to eliminate unnecessary volume and the need for void fill. Order is then auto-packed in a fit-to-size box.

Box is sealed, weighed and labeled

Box is sealed, weighed and labeled

Every box is securely sealed, weighed on the in-line scale, and automatically receives a carrier-compliant shipping label.

Watch Peppa Pig being packed fit-to-size

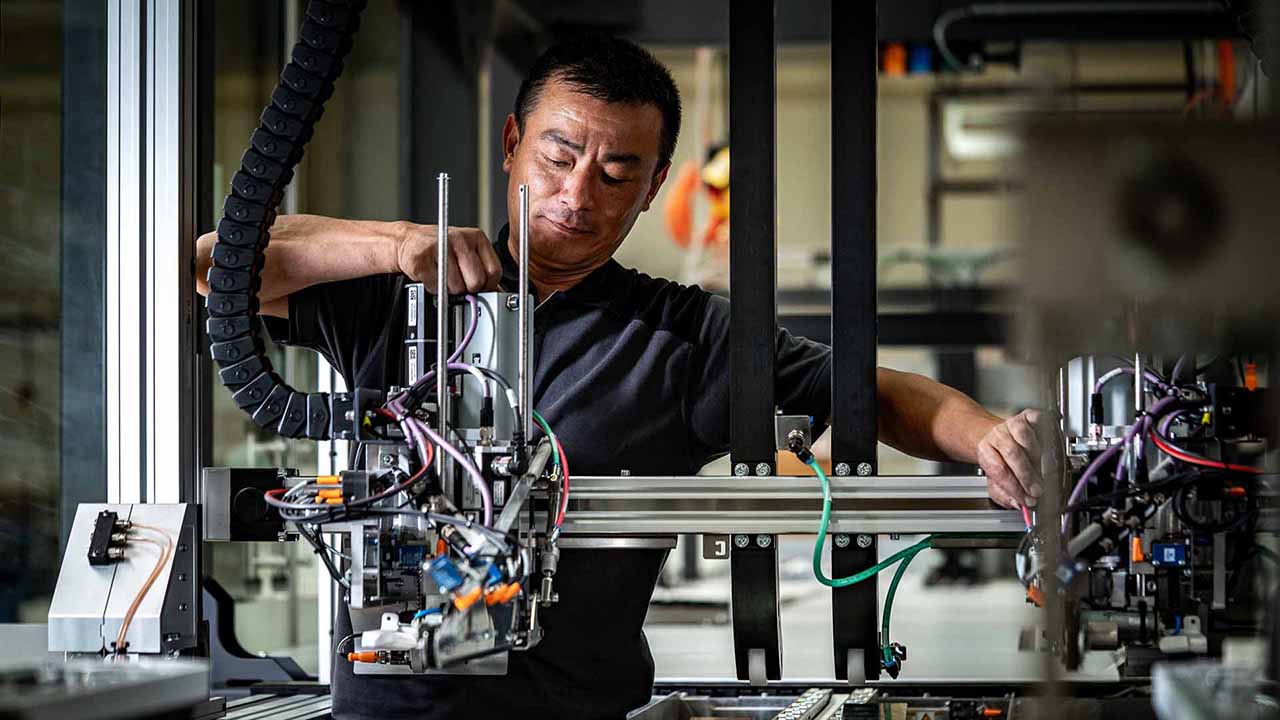

Reliable packaging

As a valued partner, our support team makes a personal commitment to deliver the best customer experience in the industry. Sparck Technologies has many assistance options that can be customized to your needs, including remote support, daily reporting, on-site services, parts support, product training, and software maintenance. Sparck’s number one priority is to ensure our customers meet or exceed their production and service levels by providing direct customer support.

Our customers are pleased with the CVP uptime and our service options which support their productivity goals, exceeding many customers expectations.

Keep your systems running at peak performance

Let’s talk about packaging

Contact us to get started and see how automated packaging can boost your business.

Create the perfect fit-to-size parcel with the lowest possible costs.

Powered by

Sparck Technologies

Meet the mid-sized and enterprise-level companies who are benefiting from the efficiency and flexibility of our automated packaging technologies.

Powered by

Sparck Technologies

Meet the mid-sized and enterprise-level companies who are benefiting from the efficiency and flexibility of our automated packaging technologies.